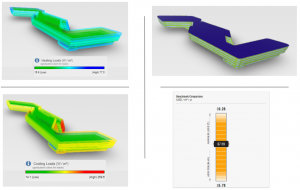

Johnson Controls (JCI) is a global leader in intelligent buildings, efficient energy solutions and integrated infrastructure systems and equipment. Johnson Controls’ new Asia-Pacific Headquarters in Shanghai showcases a full range of smart building solutions. Its sustainable design is expected to generate 44 percent savings in overall energy consumption compared to the local market standard. Additionally, the building is expected to reduce water usage by 42 percent via its grey water recycling and storm water recapture facilities, and to reduce embodied energy in materials by 21 percent.

Sophisticated sustainability analysis work was carried out throughout the design and construction of the new Facility to make sure the facility met the criteria for LEED Triple Star Platinum Certification. However, it was also important to Clay Nesler, Johnson Controls’ Vice President of Global Energy and Sustainability, that these results could be verified accurately on mainstream technologies used throughout the global AEC community so that the results achieved by JCI could be repeated accurately as they work with their clients on additional projects.

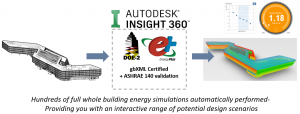

Mr. Nesler approached Autodesk’s Sustainability team, and, in turn, they enlisted the direction of Jarod Schultz, MasterGraphics.aec’s (MG.aec) Director of Research and Development. Jarod is a recognized leader on the field of sustainable design and analysis practices for his development of accurate workflows using Autodesk’s Revit, Formit, Insight, Fractal and Dynamo technologies. Mr. Schultz has been recognized for his work with Perkins+Will and Page and on various 2030 Initiatives as well. He is also an award-winning speaker on the topic at Autodesk University and BiLT conferences.

Mr. Nesler and Mr. Schultz worked with the various models and data from JCI’s new facility. Jarod worked with the models to make it function well with the other Autodesk technologies, FormIt and Insight, that would come into play. Jarod was not given access to Johnson Control’s original project results because Mr. Nesler wanted to truly see how close Jarod’s work along with the Autodesk technologies would match up.

The project took about 40 hours total, to make sure the BIM was verified correctly and that all the conditions as set up using the Autodesk technologies matched the original Johnson Controls design and engineering environment. On the eventful day of final testing, Clay could not have been more pleased, in Mr. Nesler’s words, “this is uncanny—to see not only how close the results were but also how few hours were used to generate the schematic design, design development, and construction document models.” The results were within 2% of the original JCI results and well within the margin of error.

If your firm or company requires this kind of “high bar” quality solution for early phase design, sustainability and energy analysis, total project sustainability monitoring contact the MG.aec Specialized Services team for a consultation. It is also worth noting that all the work done on the Johnson Controls, Page and Perkins+Will projects was completed using tools available in Autodesk’s AEC Collection.

For more on this project you can view Jarod’s 2018 Autodesk University recorded presentation or read Autodesk’s write-up on this customer story.

Contact MG.aec Specialized Services Team – Stan Hennigh, Business Development – Stan.Hennigh@mg-aec.com, Jarod Schultz, Director of Research and Development – Jarod.Schultz@mg-aec.com